Vessel Considerations During Post Weld Heat Treatment

by Admin

Posted on 12-09-2023 05:14 PM

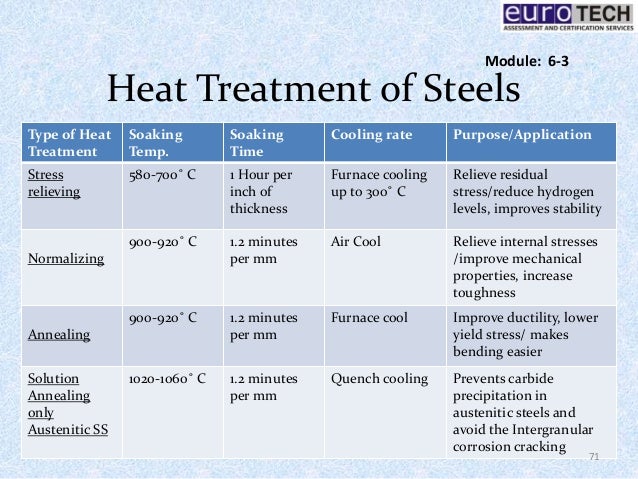

So what does the term ‘post weld heat treatment’ mean? to some engineers it is a rather vague term that is used to describe any heat treatment that is carried out when welding is complete. To others however, particularly those working in accordance with the pressure vessel codes such as asme viii, it has a very precise meaning.

When an engineer talks of post weld heat treatment, annealing, tempering or stress relief it is therefore advisable. Heat treatment following welding may be carried out for one or more of three fundamental reasons:

to achieve dimensional stability in order to maintain tolerances during machining operations or during shake-down in service.

When an engineer talks of post weld heat treatment, annealing, tempering or stress relief it is therefore advisable. Heat treatment following welding may be carried out for one or more of three fundamental reasons:

to achieve dimensional stability in order to maintain tolerances during machining operations or during shake-down in service.

The pwht is required before hydrostatic testing and following any welded repairs. For post-weld heat treatment (pwht), the manufacturer must outline the following: -how to load the furnace -placing the thermocouples: how and where -system for recording time and temperature -techniques for cooling and heating -metal temperatures and their management -supporting techniques for the vessel during pwht the aforementioned safety measures are crucial to help ensure that the entire vessel receives an acceptable pwht and to stop the vessel from deforming at temperatures above its design range. Other generic safety precautions that are significant to be taken into consideration are: equipment and panels must be grounded properly.

In short, post weld heat treatment is a critical process in the steel manufacturing industry. Without this technology, there is no way to ensure that the quality of metal production maintain the highest level. Pressure vessels and other structural steel equipment cannot be allowed to fail. However, through the post weld heat treatment, the tensile strength andcreep limit of metals have been guaranteed over the years. Grades of octg casing and tubing api standards for octg casing and tubing technological process for octg casing and tubing anti-corrosion process for line pipes standards for line pipe.

4340 Steel Heat Treatment

To be normalized, a metal needs to be receptive to normalizing, meaning its microstructure can be altered by heat treatment. Many types of alloys can be normalized, including:

metal supermarkets is the world’s largest small-quantity metal supplier with over 100 brick-and-mortar stores across the us, canada, and united kingdom. We are metal experts and have been providing quality customer service and products since 1985.

At metal supermarkets, we supply a wide range of metals for a variety of applications. Our stock includes: mild steel , stainless steel , aluminum , tool steel , alloy steel , brass , bronze and copper.

At metal supermarkets, we supply a wide range of metals for a variety of applications. Our stock includes: mild steel , stainless steel , aluminum , tool steel , alloy steel , brass , bronze and copper.

Messler rw jr (1999) principles of welding, processes, physics, chemistry and metallurgy. Wiley, new york google scholar funderburk rs (1998) key concepts in welding engineering. Weld innov xv(2):17–18 google scholar deng d, ogawa k, kiyoshima s, yanagida n, saito k (2009) prediction of residual stress in a dissimilar metal welded pipe with considering cladding, buttering and post weld heat treatment. Comput mater sci 47:398–408 google scholar totten g, howes m, inoue t (2002) handbook of residual stress and deformation of steel. Asm international, materials park google scholar lindgren l-e (2007) computational welding mechanics, thermomechanical and microstrucural simulations. Woodhead publishing, cambridge google scholar kiyoshima s, deng d, ogawa k, yanagida n, satio k (2009) influences of heat source model on welding residual stress and distortion in a multi-pass j-groove joint.

Post weld heat treatment is a controlled process which consists in heat the welded joint without reach the critical temperature of transformation (ac1). The post weld heat treatment is often usually after the union by welding of two material base such us carbon steels or alloy steels. Post weld heat treatment (pwht) can be apply to one complete piece or locally, by applying only the heat treatment to the welded joint area. The post weld heat treatment (pwht) will help to: -remove the hydrogen that could be retained in the base material after welding -reduce tensions created in the haz (heat-affected zone)

j. G. Gillissie october 1981 category: design/fabrication summary: the following article is a part of national board classic series and it was published in the national board bulletin. (4 printed pages) a short time ago during a joint review of an asme certificate holder, i found myself asking the question, "do you use heat treatment?" the immediate answer was, "oh yes. "i have asked the same question many hundreds of times in a like number of fabricators' shops, knowing full well that my question was all-inclusive and covered a number of processes. Ninety-five times out of any hundred the answer i got was a straight "yes" or "no.

In annealing, the metal is heated beyond the upper critical temperature and then cooled at a slow rate. Annealing is carried out to soften the metal. It makes the metal more suitable for cold working and forming. It also enhances the metal’s machinability, ductility, and toughness. Annealing is also useful in relieving stresses in the part caused due to prior cold working processes. The plastic deformations present are removed during recrystallization when the metal temperature crosses the upper critical temperature. Metals may undergo a plethora of annealing techniques such as recrystallization annealing, full annealing, partial annealing, and final annealing.

I’ve blathered about heat, post-weld heat treatment, heat sinking, and blown a lot of hot air in general. Mostly, the discussion has focused on weld characteristics and weldability. This blog will take a slightly different angle. Heat treating can be used for a variety of reasons: strengthening, annealing, stress relieving, and wear resistance to name a few. But, when is the best time to heat treat your welded part? generally, the answer is after all other operations are complete. But there are always exceptions. If your material (say 17-4ph stainless) welds well in a hardened condition and the final assembly is quite large, it may make more sense to harden your subcomponents prior to welding and finish machining.